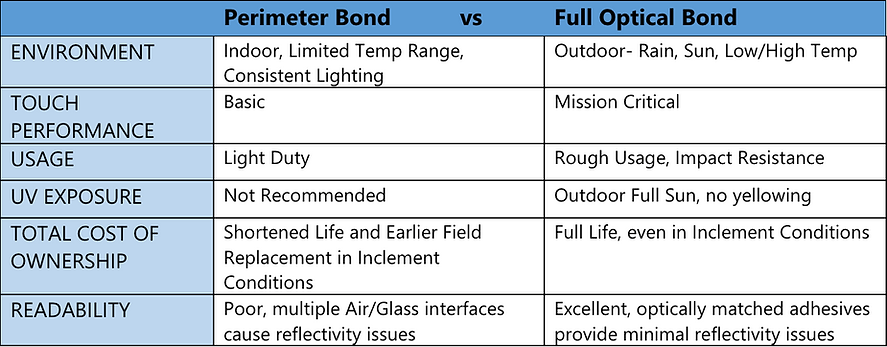

Indoor or Outdoor Application

For indoor usage, where light is controlled, a perimeter bond may be the better choice to provide good readability under consistent lighting conditions.

For outdoor usage, a full optical bond is recommended. It reduces the light transmission losses caused by the transition from glass to air and air to glass that are present when a perimeter bond is used. The Optically Clear Adhesives (OCAs) used by UICO minimize these losses for improved readability, even in bright sunlight.

Touch Performance - Basic vs Mission Critical

In a perimeter bonded assembly, the Cover Lens glass can bend, causing changes in the sensor to display spacing. These variations can lead to inconsistent touch performance.

The use of an optical adhesive layer between the touch sensor and display provides a stable mechanical assembly for more reliable touch performance.

But when cost is a primary concern, the perimeter bond may be suitable where slight variations are acceptable.

Light Duty vs. Rough Usage

In Perimeter bonded assemblies a thicker Cover Lens may be required to reduce the flex of the Cover Lens because there is nothing between the glass and the LCD. For lighter duty uses, where impacts are not expected, a perimeter bond is sufficient.

The full mechanical adhesion of an optical bond provides better support, higher impact strength, and fewer loose shards if the cover lens is subjected to an impact. The optical adhesive should never be used as a mechanical bond for mounting but can enhance the durability and safety of your assembly compared to a perimeter bond, particularly in rough usage conditions.

UV Exposure

UICO's UV-stable optical adhesives used for a full optical bond provide an extra layer of protection for your display if long term UV exposure is expected in your application. Yellowing is minimized below detectable levels.

Total Cost of Ownership

Perimeter bonded assemblies are more susceptible to potential faults caused by vibration, usage conditions, and environmental changes. In high temperature and high humidity environments, the air gap in a perimeter bonded assembly tends to capture excessive condensation resulting in fogging, faulty LCDs, reduced touch performance, as well as increased internal LCD temperatures which could shorten the LCD life. Moisture, dirt, and dust accumulating in the air gap can also cause readability and appearance issues, which could lead to early field replacement. Perimeter bonding is best for light duty indoor applications without these life-shortening conditions.

In contrast, a fully optically bonded touchscreen assembly can offer years of trouble free life when properly installed. This eliminates the need for early field replacements.

Please contact UICO to discuss your Touch sensor and Display bonding needs.

We have several proven indoor/outdoor adhesive solutions with bonding in Taiwan or China.

Custom Solutions and Larger Sizes Available - Contact UICO Sales

Schedule a Free Demo